An autoclave is a machine that uses pressured steam for a predetermined amount of time to sanitize materials and equipment. It is utilized in industrial, medicinal, and laboratory environments where it kills bacteria and spores by operating at high temperatures and pressures. All microbiological life, including bacteria, viruses, fungi, and spores, is efficiently eliminated throughout the process, guaranteeing that the sterilized objects are devoid of any live pathogens. To preserve cleanliness and avoid contamination, They are often employed in industrial, pharmaceutical, medical, and laboratory environments. It typically ranges from 121°C to 134°C, for a specific duration.

Table of Contents

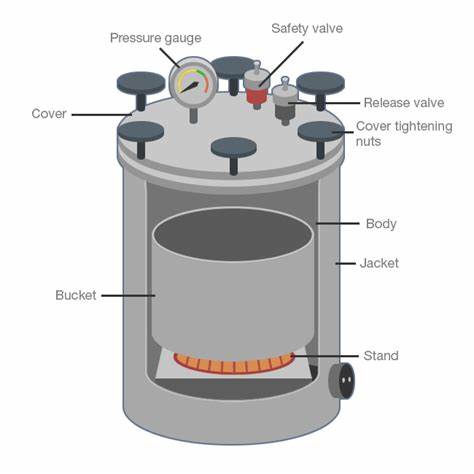

Parts of Autoclave

Pressure Chamber

The pressure chamber, which consists of an exterior jacket and an interior chamber, is the primary part of a steam. The outer chamber, which is composed of an iron casing, contains gunmetal or stainless steel in its inner chamber. To expedite the process of reaching the sterilizing temperature, and utilized medical labs are equipped with an outer jacket that is filled with steam. The items that need to be sterilized are placed in the inner chamber. The pressure chamber has a volume range of 100 L to 3000 L.

Door/Lid

The lid or door is the next crucial part of the device. The lid’s function is to isolate its’s interior from the outside air and provide a sterile environment. The asbestos washer and screw clamps make the lid sealed.

Electrical heater

Underneath the chamber is an electrical steam generator or boiler that heats the water and produces steam in both the inner and outer chambers using an electric heating system. The amount of water in the inner chamber is crucial because if there is not enough, there is a risk that the heating system will burn. Similarly, if there is more water than is needed, it might cause issues with the trays and other parts that are inside the chamber.

Vacuum generator

Certain models come equipped with an independent vacuum generator that draws air out of the chamber to produce a vacuum. Various bacteria may be able to flourish within the chamber due to the existence of air pockets. For this reason, its vacuum chamber is a crucial part.

Wastewater cooler

A mechanism to cool the effluent before it enters the drainage pipes is included in many autoclaves. Using this technique, the boiling water expelled from it won’t ever harm the drainage pipe.

Autoclave Principle

High Temperature and Pressure

The normal operating temperature range for autoclaves is 121°C (250°F) to 134°C (273°F). The autoclave creates and sustains a pressure of around 15 to 30 psi (pounds per square inch) over atmospheric pressure to reach these high temperatures.

Steam Infiltration

As the steam can permeate materials and distribute heat quickly and evenly, it is a useful sterilizing agent. Steam’s moisture aids in denaturing and coagulating proteins in bacteria, ultimately eliminating them.

Elimination of Air

Air pockets can prevent steam from penetrating the chamber, thus all of the air must be eliminated before steam can be effective.

Pre-vacuum systems actively remove air before the introduction of steam, and gravity displacement, in which steam forces air out, are two techniques for eliminating air.

Sterilization Cycle

The water in it is heated to produce steam, which raises the chamber’s temperature and pressure. Depending on the kind and quantity of material being sterilized, items are exposed to high-pressure steam for a predetermined period. Exposure periods of 15 to 30 minutes are typical. Steam is evacuated and pressure is progressively released following the exposure period. The door is left open to allow the chamber and its contents to cool.

Indicators and Validation

The proper temperature, pressure, and duration of sterilization are ensured by employing physical, chemical, and biological indicators to monitor and certify its cycles.

Autoclave Types

Laboratory bench

Nowadays, a lot of places still utilize household pressure cookers. The more recent model features a metal chamber with a rubber gasket-sealed, tight-fitting metal cover. It contains a safety valve, pressure gauge, and an air and steam discharge tap. At the base of the chamber is an electric immersion heater.

Gravity displacement

This is the typical type seen in labs. With this kind of autoclave, the heating unit generates steam within the chamber, which circulates the steam throughout the chamber to sterilize.

Type B-positive pressure displacement

This kind of autoclave uses a separate steam generator to produce steam, which is then fed into it. Because it produces steam in a matter of seconds, this autoclave operates more quickly. Compared to the gravity displacement type, this is an upgrade.

S-type displacement of negative pressure

This is an additional kind of autoclave that has a vacuum generator in addition to a steam generator. Here, the steam generator produces steam while the vacuum generator extracts all of the air from inside the autoclave. After that, the steam is sent into the autoclave. Because it delivers a high degree of sterility assurance and is highly accurate, this type of autoclave comes highly recommended.

Uses of Autoclave

- They are used to decontaminate specific biological waste and sterilize media, instruments, and labware.

- Regulated medical waste that might contain bacteria, viruses, and other biological materials is recommended to be inactivated by autoclaving before disposal.

- In medical labs, They are used to sterilize medical equipment, glassware, surgical equipment, and medical waste.

- Similarly, They are used for the sterilization of culture media, autoclavable containers, plastic tubes, and pipette tips.

What are the main parts of an autoclave?

Key parts include the chamber, door, control panel, heating element, pressure gauge, safety valve, water reservoir, steam generator, air filter, exhaust valve, drainage system, shelves or trays, and gaskets.

What items can be sterilized in an autoclave?

Items commonly sterilized include surgical instruments, laboratory glassware, media, biological waste, and certain pharmaceuticals. It is important to ensure that the items are autoclave-safe.

How does an autoclave work?

It works by using steam under pressure to achieve sterilization. The high temperature and pressure effectively kill all forms of microbial life, including bacteria, viruses, fungi, and spores.

Related Articles