Centrifugation is a widely used technique in scientific, clinical, and industrial settings for separating components of mixtures based on their physical properties. The technology takes advantage of centrifugal force to isolate materials of different densities within a liquid or suspension, offering rapid and efficient separation that would otherwise require extensive time through natural sedimentation.

An understanding of centrifuge technology is essential for professionals working in biology, medicine, environmental science, and manufacturing industries. By mastering the principles and operation of centrifuges, researchers and technicians can ensure the integrity of their results, maintain laboratory safety, and optimize workflow efficiency. This comprehensive discussion aims to cover the core aspects of centrifugation, from basic definitions to practical applications and modern innovations.

Summary of Centrifugation

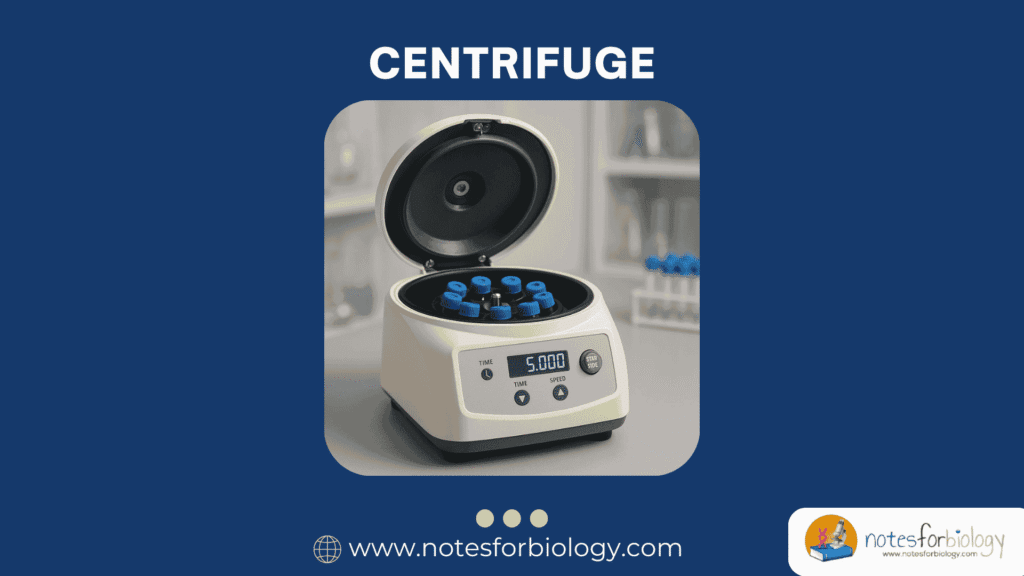

- Centrifuges are essential laboratory and industrial devices used to separate components of a mixture based on their density by spinning them at high speeds, applying centrifugal force.

- They are widely used in clinical diagnostics, research, industrial processes, and environmental analysis for tasks like separating blood, extracting DNA, clarifying liquids, and processing wastewater.

- Modern centrifuges feature digital controls, safety mechanisms, and energy-efficient designs, ensuring precise, safe, and reliable operations in diverse scientific and commercial settings.

Table of Contents

What is a Centrifuge?

Definition and Basic Concept

A centrifuge is a laboratory or industrial device that applies rapid rotational force to a mixture to separate its components based on differences in density. Heavier particles move outward toward the periphery of the rotating container, while lighter components remain closer to the center. The principle underpins a wide variety of analytical and preparative applications in scientific and industrial processes.

At its core, the centrifuge transforms rotational movement into a force capable of mimicking, and greatly accelerating, the effects of gravity. This allows even minute differences in particle density to produce effective separation within a much shorter period than would naturally occur.

Historical Background of Centrifugation

The origins of centrifugation date back to the mid-19th century, when Antonin Prandtl, a German dairy chemist, developed an early mechanical cream separator for milk processing. Over time, the concept evolved to serve laboratory and industrial needs, with significant advancements in the 20th century.

During the early 1900s, centrifuges became essential tools in biochemistry and clinical diagnostics, particularly for separating blood components. The invention of the ultracentrifuge by Theodor Svedberg in the 1920s further expanded the technology’s scientific potential, enabling the study of macromolecules such as proteins and nucleic acids. Today, centrifugation remains a cornerstone technique across numerous disciplines.

Principle of Centrifugation

Explanation of Centripetal and Centrifugal Forces

Centrifugation operates on the interplay of two forces generated during rotational motion: centripetal force and centrifugal force. Centripetal force is directed toward the axis of rotation, keeping particles moving in a circular path. Conversely, centrifugal force is the outward-directed reaction to centripetal force experienced by particles as the container spins.

The magnitude of the centrifugal force depends on the speed of rotation, the distance from the center, and the mass of the particles. Heavier particles experience greater outward force and move more quickly to the periphery, while lighter particles lag behind.

Sedimentation and Separation Principles

The actual process of separation within a centrifuge relies on sedimentation the settling of particles out of a liquid medium under the influence of centrifugal force. Particles with higher mass or density settle faster than those with lower density.

This principle allows centrifuges to achieve separations not only based on particle size and weight but also on shape and buoyancy. By adjusting rotational speed, duration, and temperature, operators can fine-tune the separation process to isolate desired components from complex mixtures.

Factors Affecting Centrifugation Efficiency

Several factors influence the effectiveness of a centrifugation process. These include the relative density of the components being separated, the rotational speed (expressed in revolutions per minute, RPM, or relative centrifugal force, RCF), the viscosity of the medium, and the duration of centrifugation.

Temperature also plays a role, as it can affect the viscosity of the liquid and the stability of biological samples. Proper selection of rotor type and centrifuge configuration further optimizes the separation outcome.

Main Parts of a Centrifuge

Rotor

The rotor is the rotating component of a centrifuge that holds the sample containers during operation. It determines the pattern and efficiency of separation based on its orientation and speed capacity. Rotors come in various designs, including fixed-angle and swinging-bucket types.

The choice of rotor affects the sedimentation path, centrifugal force distribution, and capacity of the centrifuge, making it a critical component in both laboratory and industrial models.

Motor

The motor provides the mechanical energy necessary to spin the rotor at high speeds. It is typically designed to deliver smooth, controlled acceleration and deceleration to minimize stress on samples and equipment.

Modern centrifuge motors are equipped with speed controls and braking systems for precision and safety during operation, as well as quiet, energy-efficient designs for laboratory environments.

Drive Shaft

The drive shaft connects the motor to the rotor, transmitting rotational energy and ensuring stable, balanced motion. Its design must accommodate the forces generated during high-speed rotation while maintaining alignment and durability.

Advanced drive shafts incorporate shock absorption features and materials resistant to corrosion, particularly in models handling hazardous or corrosive samples.

Control Panel

The control panel enables the user to adjust and monitor operational settings, including speed, time, temperature (for refrigerated models), and braking intensity. Digital interfaces often include preset programs, error displays, and diagnostic features.

Intuitive control panels improve operator efficiency and accuracy while providing safety alerts for issues such as imbalance or overheating.

Centrifuge Tubes and Buckets

Centrifuge tubes and buckets hold the actual samples and are designed to withstand high centrifugal forces. They come in various sizes, shapes, and materials depending on the centrifuge type and application.

Proper selection and balanced arrangement of tubes are crucial for safe operation and effective separation. Specialized buckets accommodate swinging or angled positions for different separation needs.

Safety Lid and Lock Mechanism

To prevent accidental exposure to high-speed moving parts, centrifuges are equipped with safety lids and locking systems. These mechanisms secure the chamber during operation and prevent the rotor from spinning unless properly closed.

Some centrifuges incorporate automatic lid-lock detection, ensuring that operation cannot begin until all safety checks are satisfied.

Types of Centrifuges

Based on Speed

Low-Speed Centrifuges

Low-speed centrifuges operate at speeds typically up to 5000 RPM and are used for simple separations of coarse particles and blood components. Their affordability and versatility make them popular in clinical and teaching laboratories.

High-Speed Centrifuges

High-speed models, reaching up to 25,000 RPM, are suited for more demanding applications, including cellular and subcellular separations. They often feature refrigeration for temperature-sensitive samples.

Ultracentrifuges

Ultracentrifuges exceed 100,000 RPM and are essential for isolating viruses, organelles, and macromolecules. They require sophisticated balancing and cooling systems due to the extreme forces involved.

Based on Orientation

Fixed-Angle Centrifuges

These centrifuges hold tubes at a constant angle, typically 25–40 degrees. Particles sediment rapidly along the side of the tube, making them suitable for pelleting cells and precipitates.

Swinging-Bucket (Horizontal) Centrifuges

In swinging-bucket models, tubes move from a vertical to horizontal position during operation, providing longer sedimentation paths. They are preferred for density gradient separations.

Continuous-Flow Centrifuges

Used in industrial and large-scale laboratory processes, continuous-flow centrifuges process large volumes of material without interruption, improving productivity and throughput.

Specialized Centrifuges

Microcentrifuges

Compact centrifuges designed for small sample volumes, typically under 2 mL. They are widely used for DNA, RNA, and protein extraction in molecular biology labs.

Hematocrit Centrifuges

Specifically designed to measure the proportion of red blood cells in a blood sample. Tubes are spun at high speed, and the packed cell volume is read directly.

Refrigerated Centrifuges

Equipped with cooling systems to maintain sample integrity, especially for biological and temperature-sensitive materials. They operate at a wide range of speeds.

Industrial Centrifuges

Heavy-duty models used in manufacturing and waste management industries to separate solids from liquids, such as in wastewater treatment or oil refining.

Uses and Applications of Centrifuges

Centrifugation has become indispensable across diverse fields, ranging from clinical diagnostics to large-scale industrial processes. The versatility of centrifuges lies in their ability to efficiently separate and analyze components based on density and physical properties, offering precision and speed that few other techniques can match.

In Clinical Laboratories

In clinical diagnostics, centrifuges are primarily used to separate blood components, including plasma, serum, and cellular elements. This is essential for various tests, such as complete blood counts, blood chemistry analyses, and coagulation studies. By isolating specific blood fractions, healthcare professionals can accurately assess a patient’s health status and detect pathological conditions.

Centrifuges also play a vital role in the preparation of urine sediments, cerebrospinal fluids, and other body fluids for microscopic examination. These applications support diagnostic evaluations for infections, kidney function, and neurological diseases.

In Research and Academic Labs

Research laboratories employ centrifugation for a wide range of purposes, from molecular biology to biochemistry and cell biology. It is routinely used to concentrate cells, precipitate proteins, extract nucleic acids, and purify viruses.

Density gradient centrifugation allows researchers to separate organelles such as mitochondria, nuclei, and lysosomes, enabling detailed cellular and biochemical studies. Furthermore, centrifugation is critical in genetic engineering, where it assists in plasmid isolation and transformation procedures.

In Industrial Processes

Industrial centrifuges process large quantities of materials in fields such as pharmaceuticals, petrochemicals, mining, and textiles. They are essential for tasks like separating solid impurities from liquids, clarifying suspensions, and concentrating valuable components.

In the pharmaceutical industry, centrifuges are used in the production of antibiotics, vaccines, and biological products. Meanwhile, in chemical plants, they assist in purifying solutions and reclaiming solvents, improving product quality and process efficiency.

In the Food and Beverage Industry

Centrifuges contribute significantly to the food and beverage sector, particularly in the dairy, brewing, and vegetable oil industries. They are used for cream separation from milk, clarification of juices, removal of yeast in brewing, and extraction of oils from plant sources.

These applications ensure consistent product quality, extend shelf life, and optimize production costs, making centrifugation an indispensable technology in modern food processing.

In Environmental Analysis

Environmental laboratories use centrifuges to analyze water, soil, and air samples for pollutants and microbial contamination. They help concentrate sediments, extract biological materials, and separate particulate matter from fluids.

Centrifugation is essential in wastewater treatment plants for dewatering sludge and removing suspended solids, contributing to sustainable waste management practices.

Examples of Centrifuge Applications

Practical examples help illustrate the versatility and impact of centrifugation across different fields.

Blood Sample Separation

One of the most common clinical uses of centrifugation is the separation of whole blood into plasma, red blood cells, and platelets. After centrifugation, the components settle in distinct layers, facilitating diagnostic testing and transfusion preparation.

DNA, RNA, and Protein Extraction

In molecular biology, centrifuges are used to separate nucleic acids and proteins from complex mixtures. This process typically involves lysis of cells, removal of debris by centrifugation, and subsequent extraction of target molecules for research or clinical applications.

Cell Culture Harvesting

Centrifugation is frequently employed to harvest cells grown in culture media. By spinning down the cells, researchers can remove supernatant media, wash cells, or concentrate them for further analysis or experimentation.

Wastewater Treatment

In environmental management, centrifuges assist in dewatering sludge and separating suspended solids from water. This reduces the volume of waste requiring disposal and improves the quality of treated water.

Dairy Industry Applications

Centrifuges play a pivotal role in milk processing, where they are used to separate cream from skim milk, clarify raw milk, and produce products like butter and cheese efficiently.

Safety Considerations and Best Practices

As with any high-speed equipment, centrifuges present potential hazards if not used properly. Understanding and adhering to safety guidelines ensures the protection of operators, maintains sample integrity, and prolongs equipment life.

Proper Sample Balancing

Before starting a centrifuge, it is essential to balance sample tubes by placing them symmetrically in the rotor with equal weight. Imbalanced loading can cause excessive vibration, equipment damage, and even catastrophic accidents at high speeds.

Rotor Inspection and Maintenance

Regular inspection and maintenance of rotors are critical, as even minor cracks or corrosion can compromise safety. Damaged rotors should be promptly replaced, and cleaning should follow manufacturer guidelines to prevent contamination and deterioration.

Handling Hazardous Samples

When working with infectious, toxic, or radioactive materials, sealed rotors or biosafety cups should be used to prevent aerosol formation and leakage. Appropriate containment procedures should be followed according to biosafety regulations.

Personal Protective Equipment (PPE)

Operators should wear appropriate PPE, including lab coats, safety goggles, and gloves, especially when handling hazardous or temperature-sensitive samples. This minimizes the risk of exposure to biological or chemical hazards.

Modern Innovations in Centrifuge Design

Advancements in technology have led to the development of centrifuges with improved safety, efficiency, and user-friendly features, meeting the evolving needs of laboratories and industries.

Digital Control Interfaces

Modern centrifuges often feature digital touch screens and programmable settings, allowing precise control over speed, time, temperature, and acceleration/deceleration profiles. These interfaces enhance usability and minimize human error.

Automatic Imbalance Detection

Many contemporary centrifuges include automatic imbalance detection systems that halt operation when uneven loading is detected. This protects both the operator and the equipment from potential damage.

Energy-Efficient and Low-Noise Designs

Centrifuges now incorporate energy-saving motors and soundproofing technology to reduce energy consumption and operational noise, creating a safer and more comfortable work environment.

Common Troubleshooting Issues

Centrifuge users may encounter operational challenges that require prompt troubleshooting to maintain efficiency and safety.

Rotor Imbalance and Vibrations

Excessive vibration often indicates an imbalance in the rotor, either from uneven sample loading or a damaged rotor. Operators should stop the machine, inspect the setup, and rebalance or replace components as necessary.

Temperature Control Failures

In refrigerated centrifuges, temperature fluctuations can affect sample stability. Regular maintenance of the cooling system and monitoring of temperature readings ensure consistent performance.

Error Messages and Diagnostic Features

Modern centrifuges display error codes to indicate specific issues, such as lid lock failure, motor malfunction, or imbalance. Operators should familiarize themselves with diagnostic codes and follow troubleshooting protocols provided in the user manual.

Choosing the Right Centrifuge

Selecting the appropriate centrifuge depends on several factors, including the nature of the application, operational requirements, and budget.

Application-Specific Criteria

Consider the type of materials being separated, the required speed and RCF, sample volume, and whether refrigeration or containment features are necessary. Applications such as blood banking, molecular biology, or industrial processing may demand specialized models.

Capacity and Speed Requirements

Laboratories handling large numbers of samples or needing high-speed separations must select centrifuges with appropriate capacity and speed ranges. Microcentrifuges suit small-volume, high-speed applications, while continuous-flow models handle large-scale operations.

Budget and Brand Considerations

Cost is a significant factor in equipment procurement. While premium centrifuges offer advanced features, reliable mid-range models can meet the needs of most laboratories. Brand reputation, warranty, and after-sales support should also influence purchasing decisions.

Ethical and Environmental Aspects

Modern laboratory practices emphasize safety, environmental responsibility, and regulatory compliance.

Safe Disposal of Biological Waste

Samples processed in centrifuges, particularly those involving infectious or toxic materials, should be disposed of according to biosafety guidelines. Proper waste segregation and sterilization protect personnel and the environment.

Energy Consumption Concerns

Given their high-speed motors and cooling systems, centrifuges consume considerable energy. Energy-efficient models and responsible usage, such as minimizing idle time and performing routine maintenance, help reduce environmental impact.

Compliance with Laboratory Safety Standards

Adherence to national and international safety standards ensures that centrifuges operate safely and efficiently. Institutions should establish clear safety protocols, conduct routine training, and perform regular equipment audits.

Conclusion

Centrifuges are indispensable tools across scientific, medical, and industrial fields. Their ability to separate mixtures rapidly and efficiently based on density differences has transformed research and diagnostic capabilities worldwide. From blood analysis to DNA extraction, environmental testing to dairy processing, centrifugation continues to evolve through innovations in design, safety, and energy efficiency.

As future trends focus on automation, digital control, and sustainable operation, the centrifuge remains at the heart of laboratory and industrial processes. A comprehensive understanding of its principles, components, applications, and safety considerations is essential for anyone working in environments where precision separation is required.

Frequently Asked Questions (FAQ)

What are the main factors affecting centrifuge performance?

The key factors include the speed (RPM), relative centrifugal force (RCF), rotor type, sample balance, temperature control, and the density of the materials being separated. All of these influence how efficiently and safely a centrifuge can separate different components.

How do you select the correct rotor for an application?

You choose a rotor based on what you’re spinning (liquid or solid samples), the volume and size of your tubes, the speed required, and whether you need a fixed-angle or swinging-bucket setup. Some applications, like density gradient separations, need specific rotors designed for precise control.

Can centrifuges be used for non-scientific purposes?

Yes centrifuges aren’t just for labs! They’re used in industries like dairy (to separate cream from milk), juice clarification, oil extraction, and even washing machine spin cycles, where the same principle of separating materials by spinning is applied.

Related Contents

Celsius vs Fahrenheit Scale: 10 Key Differences with Real-World Examples

Cell Proliferation – Definition, Assay, Differentiation, Diseases