Batch and fed-batch and continuous culture methods are methods of growing microorganisms, where batch culture involves growing microorganisms in a fixed volume of nutrient medium until it is exhausted, fed-batch culture adds nutrients at intervals to prolong growth, while continuous culture maintains a constant environment by continuously adding fresh medium as the medium is removed. These three methods of culture – batch and fed-batch and continuous culture – are commonly applied in industrial fermentation, microbial cultivation, and bio-processing. Every method possesses distinct qualities, benefits, and constraints, making them appropriate for various uses in biotechnology, pharmaceuticals, and environmental processes.

Table of Contents

Batch Culture Technique

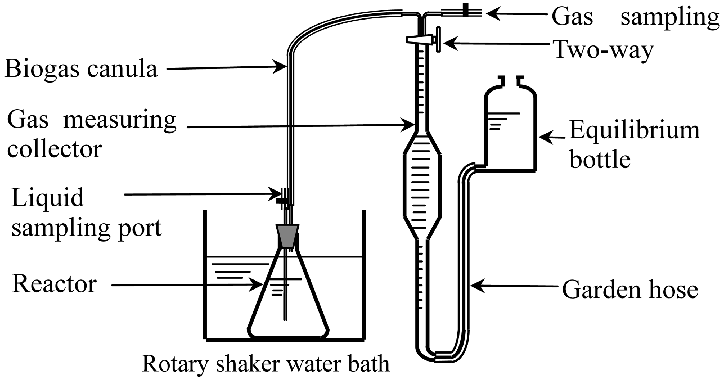

Batch culture, a method frequently utilized in biotechnology, microbiology, and industrial fermentation processes, refers to a type of microbial cultivation. Microorganisms like bacteria, yeast, or fungi are cultivated in a set amount of nutrient medium within a sealed system in batch culture. The procedure involves adding necessary nutrients at the start of the culture and allowing microorganisms to multiply without adding more nutrients or removing waste products throughout the culture.

Key Features

Closed System: Nutrients cannot be added, and waste cannot be removed throughout the process.

Constant Volume: The culture medium’s volume does not change.

Growth in one phase: Microorganisms experience a consistent growth sequence: lag phase → exponential phase → stationary phase → death phase.

Fed-Batch Culture Technique

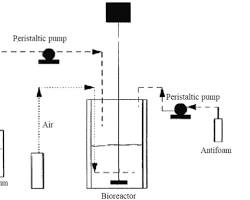

Fed-batch culture is an altered form of the traditional batch culture method, developed to overcome certain constraints of batch procedures like nutrient exhaustion and the buildup of harmful byproducts. In a fed-batch setup, nutrients are not all given at once but are added slowly or in intervals during the culture process. This method provides better control over growth conditions and allows the culture to thrive in an ideal environment for longer periods, resulting in increased microbial growth and higher product yields.

Key Features

Semi-open System: Nutrients are introduced while waste products are not constantly eliminated throughout the fermentation process.

Regulated Feeding: Nutrient intake is monitored closely to avoid overfeeding, which may cause unwanted by-products or excessive expansion.

Prolonged Growth Stage: Microorganisms have the ability to stay in the exponential growth phase for an extended period, resulting in a higher production of the desired product.

Continuous Culture Technique

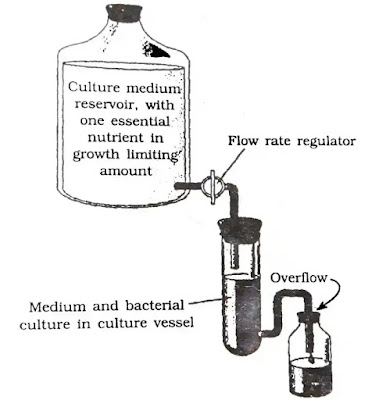

Continuous culture involves constantly providing new culture medium to a bioreactor while also removing the same amount of culture medium, along with microorganisms and byproducts. This procedure establishes a stable setting where microorganisms are able to thrive non-stop, provided that the nutrient supply, pH, temperature, oxygen levels, and other parameters are maintained at ideal levels.

Key Features

Open System: Ongoing flow of nutrients and disposal of waste materials.

Sustained Growth: The culture continues to experience exponential growth without interruption in ideal circumstances.

Volume remaining consistent: The culture’s volume remains unchanged by ensuring the rate of inflow matches the rate of outflow.

Similarities Among Batch and Fed-Batch and Continuous Culture

Microbial Growth and Metabolite Production: All three methods; batch and fed-batch and continuous culture utilize the growth of microorganisms to generate specific products such as metabolites, enzymes, or biomass.

Nutrient Provision: All three methods; batch and fed-batch and continuous culture supplies necessary nutrients for microorganism growth, but the delivery method and schedule vary.

Closed Bioreactor Environment: Bioreactors in a closed environment regulate temperature, pH, and oxygen levels to support ideal growth.

Accumulation of waste products: Microorganisms in every system; batch and fed-batch and continuous culture generate substances that may impact growth, but their elimination procedures vary.

Maximizing production: The primary objective of each of the three methods is to increase the production of the targeted product, whether it be biomass, metabolites, or other bio-derived compounds.

Difference between batch and fed-batch and continuous culture technique

| Feature | Batch Culture | Fed-Batch Culture | Continuous Culture |

|---|---|---|---|

| Nutrient Supply | All nutrients are included in the initial stage. | Nutrients are consistently included at intervals throughout the process. | Nutrients are consistently provided throughout the entire process. |

| Culture Volume | Stays consistent during the entire procedure. | Volume grows when nutrients are introduced. | The volume stays the same because the medium is taken out at the same speed as it is put in. |

| Growth Phases | Microbes experience lag, exponential, and stationary stages. | Controlled feeding can prolong the exponential phase. | Microorganisms remain in the exponential phase, experiencing steady-state growth. |

| Waste Management | Waste builds up due to the lack of waste removal. | Nutrient feeding regulates the accumulation of waste. | The medium ensures that waste is consistently eliminated, avoiding accumulation. |

| Complexity | Easy installation and usage. | Needs increased supervision and regulation of feeding speeds. | The most complicated aspect due to constant monitoring and control of nutrients and waste. |

| Operation Time | Usually concludes once the nutrients have been exhausted. | Operates for long durations by constantly supplementing nutrients. | Can continue to operate ceaselessly if criteria are upheld. |

| Product Yield | Nutrient depletion restricts yield potential. | Higher production rates are achieved compared to batch culture due to the ability to prolong growth. | Greatest output is achieved by continual exponential growth and stable conditions. |

| Inoculum size | A small amount of inoculum introduced at the beginning. | Inoculum size resembles batch culture, yet growth lasts longer. | The size of the inoculum is small, but growth remains constant. |

| Product Concentration | The level of product rises until all nutrients are depleted. | Controlled feeding can help maintain product concentration for a longer period of time. | The concentration of the product remains low because it gets diluted with new medium. |

| Risk of Contamination | The risk of contamination rises as the process advances. | The risk of contamination is medium since adding nutrients decreases the duration of time spent in the stationary phase. | Continuous culture has minimal risk under stable conditions, but the risk increases if the system is disrupted. |

| Nutrient Limitation | Nutrient limitation occurs when the initial nutrients are used up. | Controlled feeding prevents nutrient deficiency. | Regulating the dilution rate controls the limitation of nutrients. |

| Oxygen Demand | The need for oxygen rises as microbial growth occurs, yet it becomes restricted in the stationary phase. | Adding nutrients can help regulate the oxygen consumption by controlling demand, which enables growth to persist. | The need for oxygen remains steady as growth continues to follow an exponential pattern. |

| Byproduct Formation | Accumulation of byproducts may occur, potentially hindering both growth and product development. | Nutrient feeding can help manage the accumulation of byproducts, which occurs at a reduced pace. | By removing byproducts continually, accumulation is avoided. |

| Process Control | Straightforward, needing just the initial configuration. | Requires precise management of nutrient addition speeds. | Necessitates accurate regulation of nutrient supply, waste elimination, and various other factors. |

| Cost of Operation | Usually decreased, because the configuration is more straightforward. | More costly because of the necessity for ongoing nutrient supplementation and supervision. | The high cost is a result of the challenges involved in keeping a stable system with ongoing monitoring and control. |

Frequently Asked Questions (FAQ)

Which culture system is best for high product yield?

Among batch and fed-batch and continuous culture, continuous Culture usually offers the greatest product yield by keeping microorganisms in the exponential growth phase for a prolonged period. Feeding nutrients gradually in a fed-batch culture can lead to increased yields by prolonging the productive growth phase.

What is a chemostat in continuous culture?

A chemostat is a form of continuous culture in which the rate of growth of microorganisms is regulated by restricting the availability of a particular nutrient. The flow rate of the medium is modified in order to keep a stable condition where the rates of growth and removal are equal.

What is the role of a bioreactor in these culture systems?

A bioreactor is utilized in each of the three systems to offer a regulated setting for microbial proliferation, while upholding factors such as temperature, pH, oxygen, and agitation. It also enables the incorporation of nutrients and elimination of waste in fed-batch and continuous systems.

Related Articles